Decanter Mechanism

Decanter as Dependable as Gravity

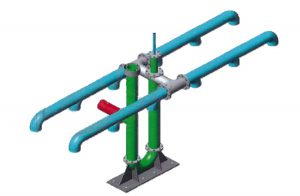

The utility model discloses a rotary siphon water decanting machine comprising a water decanting mechanism, a siphon mechanism, a lifting mechanism, a control mechanism and a frame. The utility model relates to a solid-liquid separation, The separation of liquid transfer device, In particular relates to a sewage treatment system for environmental protection. The use of gap type activity in sewage treatment. Wastewater treatment method that SBR process decanter machine rotary siphon. The water decanting mechanism is mainly formed of a water decanting hanging basket, a swinging arm, a water-supply rotating connector, a launching rotating connector, a lower articulated joint base and a lower water valve pipe, where in the water decanting hanging basket is connected with swinging arm by the water-supply rotating connector. The swinging arm ins connected with the lower water valve pipe by the launching rotating connector and the lower articulated joint base.

The Decanter Difference

Fixed or Floating Decanter. Because our system is valve less it can’t jam, close or otherwise fail, interfering with the decant. But we still offer plenty of control over the decant. When th SBR water level reached the operator selected bottom water level, atmospheric air breaks the siphon stopping all decant flow. Decanting makes it virtually impossible to discharge untreated waste water into treated clean water.

Reliable construction. No submerged Flex-Hose is used that can fail over time.

Header. The header is located above the liquid surface at all times. Our process does not use solids excluding plugs that can clog. Plus our low inlet velocity, eliminates vortex mixing of scum or sludge. Decant can begin sooner relative to deep draw decanters with an adjustable inlet elevation of 4″ to 12″ below water line during decant.

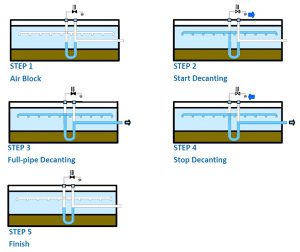

Process principle

The Decanter Advantages

- Simple and safe to operate.

- Constructed of high quality ductile/stainless steel for years of durable, corrosive resistant operation.

- lower than 0.6 ft. per second inlet velocity allows for decant start as early after the start of a setting phase as possible.

- Adjustable inlet header elevation is from 4″ to 12″ at the surface of the tank.

- Impossible to allow discharge at any time other then when “decant” is signaled.

- Impossible to “leak” any of thank contents in the event of any component failure or malfunction of the SBR equipment.

- No underwater components in the SBR tank.

- Only two moving parts, a vacuum blower and a swivel joint, both always above the surface of the SBR tank contents.

- Automatically decant stop at a preset low water level in the event of a plant control or instrumentation error, power outage, or other plant malfunction.