RAS pump

RAS pump

RAS pump (Return Activated Sludge Pump)

Return Activated Sludge Pump

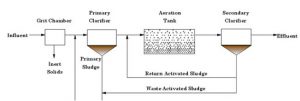

An activated sludge process refers to a multi-chamber reactor unit that makes use of highly concentrated microorganisms to degrade organics and remove nutrients from wastewater to produce a high-quality effluent. To maintain aerobic conditions and to keep the activated sludge suspended, a continuous and well-timed supply of oxygen is required.

Activated sludge consists of flocs of bacteria, which are suspended and mixed with wastewater in an aerated tank. The bacteria use the organic pollutants to grow and transform it to energy, water, CO2 and new cell material. Activated sludge systems are suspended-growth type and are used in conventional high-tech wastewater treatment plants to treat almost every wastewater influent as long as it is biodegradable. A physical pre-treatment unit, a post-settling unit (a clarifier) from which active sludge is re-circulated to the aerated tank, and excess sludge treatment, are compulsory for appropriate treatment. The process is highly mechanised and thus mainly adapted for centralised systems where energy, mechanical spare parts and skilled labour are available. Provided the reactor is well operated, a very good removal of organics and suspended solids can be achieved, though pathogen removal is low.

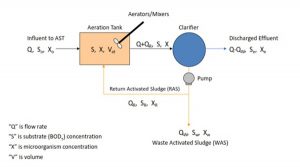

The term activated sludge refers to suspended aerobic sludge consisting of flocs of active bacteria, which consume and remove aerobically biodegradable organic substances from screened or screened and pre-settled wastewater. Activated sludge systems can treat blackwater, brownwater, greywater, faecal sludge and industrial wastewater as long as the pollutants to be treated are biodegradable. Schematic of the aeration tank and secondary settling tank (clarifier) of an activated sludge system. Activated sludge reactors are aerobic suspended-growth type processes (in opposition to fixed-film or attached-growth processes). Different configurations of the activated sludge process can be employed to ensure that the wastewater is mixed and aerated in an aeration tank. Aeration and mixing can be provided by pumping air or oxygen into the tank or by using surface aerators. The microorganisms oxidize the organic carbon in the wastewater to produce new cells, carbon dioxide and water. Although aerobic bacteria are the most common organisms, facultative bacteria along with higher organisms can be present. The exact composition of bacteria depends on the reactor design, environment, and wastewater characteristics.

The flocs (agglomerations of sludge particles), which form in the aerated tank, can be removed in the secondary clarifier by gravity settling. Some of this sludge is recycled from the clarifier back to the reactor. The effluent can be discharged into a river or treated in a tertiary treatment facility if necessary for further use.In the view of reuse of the effluent in agriculture, it is not beneficial to remove all nutrients while standards for pathogen removal are barely met.As the system is also of high complexity and strongly mechanised, it is mainly adapted for centralised systems where energy, mechanical and technical spare equipment and skilled staff are available.

The activated sludge process:

- Is a form of aerobic biological treatment for reducing soluble BOD (dissolved organic

matter)

- Involves the suspension of microorganisms within the wastewater in a reactor (aeration

tank or basin) — A suspended growth process

- Recycles a portion of the microorganisms back into the reactor, which decouples

micro-organism retention time (“solids retention time”) from hydraulic residence time

[microorganism concentration is independent of hydraulic residence time]

Objectives for Activated Sludge Treatment

- Significant reduction (≈85 to >95% removal) in BOD concentration (low BOD in

treated effluent)

- Production of a sludge with good settling and compaction properties (low TSS in clarified

effluent)

NPDES permits for municipal sewage treatment and industrial wastewater treatment

routinely specify discharge limits on BOD and TSS

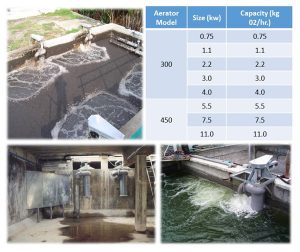

Catalog for RAS Pump

| item | Size (kw) | Dia. 150 | Dia. 200 | ||

| Speed | Capacity | Speed | Capacity | ||

| (rpm) | (m3/hr) | (rpm) | (m3/hr) | ||

| 1 | 0.75 | 324 | 120 | – | – |

| 2 | 1.1 | 409 | 151 | 324 | 146 |

| 3 | 1.5 | 461 | 171 | 409 | 184 |

| 4 | 2.2 | 514 | 190 | 461 | 207 |

| 5 | 3.0 | 576 | 213 | 514 | 231 |

| 6 | 4.0 | 642 | 238 | 576 | 259 |

| 7 | 5.5 | – | – | 642 | 289 |

Activated sludge processes are one part of a complex wastewater treatment system They are usually used following primary treatment (including screening that removes settleable solids), include one or more main aerated treatment chambers, aeration devices, a device for appropriate mixing to keep the sludge in suspension, a secondary clarifier to separate the biomass from the treated effluent and collect settled biomass, generally a non-linear, highly complex circulation regime (e.g. recirculation loops, by-passing etc.) and are sometimes followed by a final polishing step (see tertiary filtration and disinfection). The biological processes that occur are effective at removing soluble, colloidal and particulate materials. The reactor can be designed for biological nitrification and denitrification, as well as for biological phosphorus removal.

The design must be based on an accurate estimation of the wastewater composition and volume. Treatment efficiency can be severely compromised if the plant is under- or over-dimensioned. Depending on the temperature, the solids retention time (SRT) in the reactor ranges from 3 to 5 days for BOD removal, to 3 to 18 days for nitrification.

The excess sludge requires treatment to reduce its water and organic content and to obtain a stabilized product suitable for end-use or final disposal. It is important to consider this step in the planning phase of the treatment plant).