Intermittent Decanted Extended Aeration (IDEA)

Intermittent Decanted Extended Aeration (IDEA)

Intermittent Decanted Extended Aeration (IDEA)

Intermittent Decanted Extended Aeration (IDEA) System

- IDEA is an advanced technology of Sequencing Batch Reactor (SBR).

- Combine aeration and sedimentation in the same tank.

- Extended aeration provides sufficient oxygen to reach endogenous phase, thus small sludge production and high BOD removal.

- Unique decanter operates with hydraulic principle, controlled by solenoid valve. No moving part, hence easy to maintain.

Advantages of IDEA

- Lower civil cost as construction is less complicated

- Requires smaller area

- High quality of effluent and low volume of sludge

- Minimizes fluctuation in effluent quality

- Nitrogen and phosphorus removal

- Simple operation and low maintenance

- Odour free and quiet operation

- PLC operation (optional)

- Flexible for various types of influent

- Evens out fluctuating hydraulic and organic loads

- Less equipment for pretreatment, i.e. normally does not need grease trap, equalization tank, fine screen

IDEA Intermittent Decanted Extended Aeration

1. INTRODUCTION

BKT provide varius types of treatment systems. The IDEA Intermittent Decanted Extended Aeration Activated Sludge System is a span’s approved system and has been widely adopted in Thailand.

In the IDEA single tank treatment process, sewage in nitrified and denitrified in a same reactor. Total-N concentration of 15 mg/l on a 90 percentile basis are typically achieved.

In the dual tank IDEA treatment process, Demand Aeration Tank prevents short-circuiting and maximizes nitrification. The aerobic and anoxic periods are optimized by automatic dissolved oxygen control and variable PLC timer controls. Total-N concentrations of 6 mg/l on a 90 percentile basis are achieved.

The dual tank process also ensure Sludge Volume Index (SCI’s) is lower than 100 mg/l which provides process stability. The combination of the dual tank process and the gas locked siphon decanter results in a reliable process which can consistently produce low levels of Total-N.

2. SINGLE TANK IDEA PROCESS

The IDEA process or Sequenced Batch Reactor (SBR) process are different names for similar processes. The essential difference is that the SBR process is normally sequence fed, whereas the IDEA process is continuously fed.

In its simple form the IDEA process is one of carry out the following function in a single reactor.

- Synthesis

- Nitrification

- Denitrification

- Endogenous Decay

- Secondary Clarification

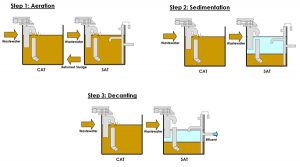

A typical dry weather cycle for a single tank system is : 2 hours aerate, 1 hour settlement, 1/2-1 hour decant. The process is illustrated graphically as Figure as below.

3. HYBRID DUAL TANK IDEA PROCESS

Experience has shown that most single tank IDEA processes, and to a lesser extend SBR processes, suffer from very poor sludge settlement characteristics under design load condition (SVI’s greater than 200). This is primarily due to the fact that for almost 50% of the time (settle and decant period) microorganisms are trying to grow i as oxygen limited environment, which is a well known condition for promoting filamentous organisms (bulking sludge).

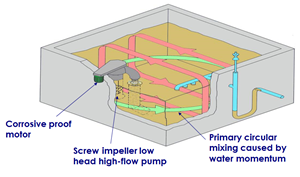

Dual tank IDEA process has addressed the limitations of single tank processes by providing and demand aeration tank prior to the intermittent tank, and incorporating a recycle activated sludge (RAS) steam. However the main advantages and feature of the intermittent decanted process are still retained. Figture as below illustrates the process.

3.1 Advantages of Hybrid Dual Tank Process

The main advantages of the two stage approach are summarized below :

a) Synthesis is optimized and growth does not take place in an oxygen depleted environment. SVI’s less than 100 are consistently achieved.

b) With a rapidly setting sludge in the intermittent tank, a high degree of anoxic denitrification is difficult to achieve. The demand tank is used to optimize denitrification by the really available carbon in the feed sewage.

c) In the demand tank is provided on demand. Hence a more effective usage of installed aeration capacity is achieved.

d) Endogenous decay is not limited, by providing oxygen on demand to the decaying organism. Hence a lower more stabilized sludge make is achieved.

e) The potent for shot circuiting, particularly in cold climate, during the settlement and decant period is eliminated.

f) In the demand tank oxygen is provided on demand even during peak wet weather flow, ensuring adequate treatment during wet weather.

3.2 Gas locked Siphon Decanting

Another innovative aspect of the hybrid process is the patented gas locked siphon decanter. This is a major Australian development and has been used in over more than 1,000 plants since 1983. It is simple idea with only one moving part and it is and improved alternative to lowering or hinged weir decanters.

The operation of the GLS is described in Figture c below. When the water level is rising in the intermittent extended aeration cycle, air is trapped in a submerged weir and pressurized against a balancing water column contained in the outlet pipe. Maxed liquor or unsettle effluent is prevented from entering the submerged weir at all tank levels by the trapped air.

After a settlement period the trapped air is vented, priming the siphon and allowing solids-free effluent to leave the plant. The siphon is broken at bottom water level to stop the decanting and the treatment cycle is then repeated. See Figure as below:

The main features are :

a) The GLS decanter can be supported on a basic concrete footing. No complex civil structures are required.

b) Weir loading rates are comparable to conventional continuous clarifiers

c) It can sustain relatively high MLSS concentrations and has a greater ability to handle bulking sludge.