screw press dewatering continuous

Screw press dewatering continuous

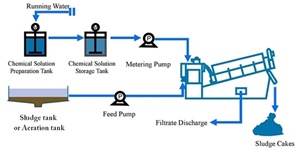

Process Diagram

Sludge, first feed into the Flow Control Tank, flows into the Flocculation Tank Where polymer coagulant is added. From there, the flocculated sludge overflows into the dewatering drum where it is filtered and compressed. The entire operation sequence, including sludge feed control, polymer makeup, dosing and sludge cake discharging id controlled by the built-in timer and sensors of the control Panel

Generally speaking, in the precedent stage of sludge dewatering, there is a sludge thickening tank for pre-thickening of sludge and a sludge storage tank for storing the thickened sludge. The sludge in the sludge thickening tank or sludge storage tank gives off offensive odors as time passes while the thickening and dewatering treatment is processed. Direct dewatering of low concentration sludge from the oxidation ditch (aeration tank) with Volute removes odor by dewatering fresh aerobic sludge, reduces investment costs for thickening and storage equipment and operation costs. Furthermore, phosphorus in waste activated sludge can be efficiently captured in the dewatered sludge cake, which reduces the load of returning phosphorus to the wastewater treatment. In addition, the condition of the sludge in the oxidation ditch (aeration tank) is always stable, which further contributes to the stable dewatering process.

Technical Advantages

Direct treatment of thin sludge Multi-Disk Screw Press is capacity of dewatering low-concentrated sludge from a biological process, such as an oxidation ditch, which decreases phosphorus in return water from sludge treatment.

Low operational cost Energy efferent design of Multi-Disk Screw Press requires power consumption as low as 0.18 kW and water consumption as low as 64g/min.

Stress–free maintenance A partial overhaul of the Dewatering Drum is a half-day work and it can be undertaken on site easily.

Wide variety of sizes Multi-Disk Screw Press Comes in a variety of sizes suitable for small septic as well as large scale wastewater treatment plants.

24–hour automated operation Multi-Disk Screw Press with its clog-free design operates fully automatic for 24 hours and it only requires periodic and chemical. replenishment.

Clog–free construction Built-in self-cleaning system handles oily sludge without clogging and requires no rinsing water to prevent clogging.

Compared with other system

| Compare | BKT Screw Press | Belt Press | Centrifugal |

| Low concentrated of sludge | Yes | No | No |

| 24 hours self–service running | Yes | No | No |

| Sludge thickener | No need | Need | Need |

| Sludge tank | No need | Need | Need |

| Power consumption | Very little | Maximum | Much |

| Cleaning drench water quantity | Very little | Maximum | Much |

| Operation noise, vibration | Small | Big | Small |

| Sludge viscous requirement | Low | High | High |

| Area for installation | Small | Much | Medium |

Screw press dewatering continuous

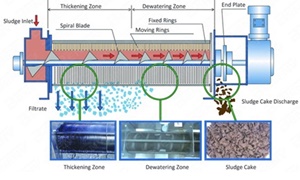

The Screw Dewatering Press belongs to the screw press, it’s clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. BKT using screw and the moving rings to clean itself as clog-free structure, and controlled by the PLC automatically, it’s a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

The Screw Dewatering Press is an enclosed high performance sludge dewatering system. It utilizes a central screw auger and a slowly oscillating multi-disk filter to gradually increase pressure on flocculated sludge to produce an exceptionally dry sludge cake. With electrical, water and polymer usage, and high capture rates the system is very cost effective.

The Screw Dewatering Press can be provided with all equipment required for dewatering included and factory mounted, piped and wired on a single stainless steel skid. This equipment includes the sludge pump, wash water pump, polymer dosing system and control panel. The system features fully automated one pushbutton startup and shutdown. Once started up the system can run unattended and can be set to shutdown automatically with no operator intervention.

The Screw Dewatering Press is constructed entirely of stainless steel.

The Screw Dewatering Press features:

- Enclosed to minimize odors and noise

- Very low wash water usage(1/8 compared with belt press)

- Very low power consumption(1/20 compared with centrifuge)

- High cake solids

- Minimal operator requirement

- Easy to operate and maintain

- Auto start-up, run and shutdown

- Touch screen operation optional

- Sludge Flow and Cake Monitoring System

- Available with many other options like Dairy, Palm Oil, etc.

These technical systems require a high degree of operator supervision, and operator training. The mechanical systems such as filters, belts, tensioning systems or bearings have to be maintained correctly to guarantee proper functioning. The performance of primary treatment systems prior to mechanical stage is also a critical determinant of performance. Primary treatment commonly includes the removal of gross solids, and slurry thickening. Routine use of flocculants is essential, normally selected at installation using advice and the results of on-site testing from polymer chemical suppliers.

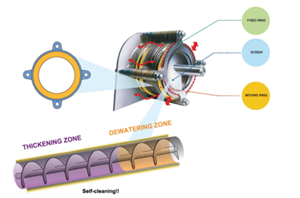

The initial section of dewatering drum is the Thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gaps between the rings decrease at the end of dewatering drum, hence increasing its internal pressure. At the end, the End Plate further increases the pressure, so as to discharge dry sludge cake..

Design and Function

Layers of spacers, Fixed and Moving Ring are secured in place on the tie rod. The inner diameters of Moving rings are slightly smaller than the outer diameter of screw and those rings, mobilized by the screw, continuously clean sludge out of the gaps and prevent clogging.

Technical Advantages

- Compact Design

- Easy Maintenance

- Small Footprint

- Easy Installation

Reduce Construction Cost

- Multi-Disk Screw Press has built-in thickening zone which eliminates the need for a thickener, sludge storage, or separate dosing facilities. Multi-Disk Screw press is all-in-one construction which makes it very compact and economical.

screw press dewatering continuous

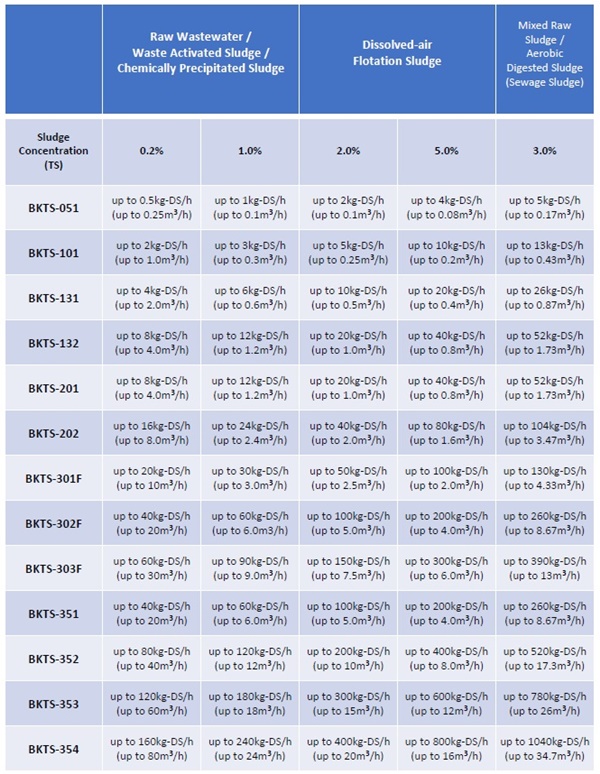

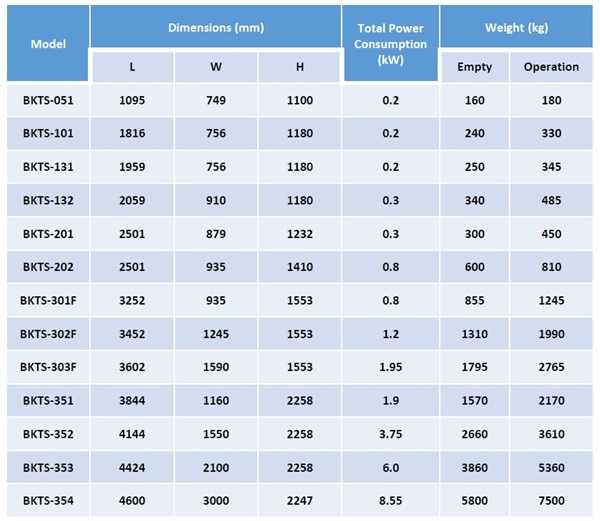

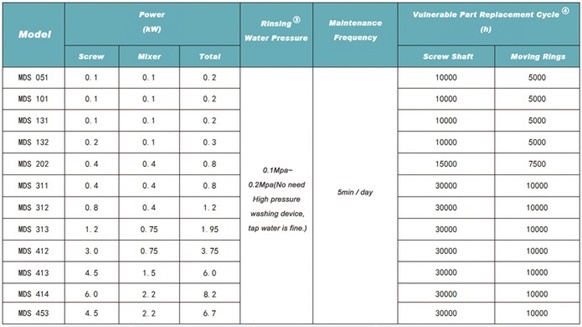

Specification list Condition – BKT screw

Running condition

Replacement time of vulnerable part is an estimated time, in the actual operation process, the types of sludge, the means of processing, operation adjustment status and the running time of the day, will affect the replacement time.( Replacement cycle of vulnerable part is calculated as 365 days per year, 8 hours/day of running time.)

Model reference

* Throughput of each model is based on sludge cake with 85% water content.

* There is no certain upper limitation on inlet sludge concentration, however, the target

sludge must be flow able.

* Throughput of DAF Sludge is based on sludge containing much fat, oil, and grease

such as meat processing applications etc.

* Throughput of Mixed Sludge (Primary Sludge and Waste Activated Sludge) and

Aerobically Digested Sludge is based on sludge containing more than 30% fiber

(200 mesh) against Total Solids.

Specification